Mechanical Engineering

- Department Profile

| Program | Specialization | Duration | Sanctioned Intake |

|---|---|---|---|

| B Tech | Mechanical Engineering | 4 Years | 30 |

The Department of Mechanical Engineering was established in the academic year 2004-2005, offers B-Tech (Mechanical Engineering) Programme with the intake of 30. The B-Tech Degree Programme is affiliated to APJ Abdul Kalam Technological University since the academic year 2015-2016.The Department aims to equip students with the ability to solve complex engineering problems across Design, Manufacturing, and Thermal Engineering domains. It fosters curiosity and innovation through interdisciplinary learning, encouraging the development of entrepreneurial ideas. Graduates are trained to become effective professionals capable of addressing real-world challenges by applying their mechanical engineering knowledge. Emphasis is placed on preparing students to use their engineering and problem-solving skills in professional practices, while also addressing societal issues and business challenges. Furthermore, the program instills strong ethical values and nurtures essential communication, teamwork, and leadership skills to ensure graduates are well-rounded and industry-ready.

- PEOs, POs and PSOs

Program Educational Objectives(PEOs)

| PEO1 | Knowledge Develop graduates as effective professionals by solving complex real world challenges through the use of Mechanical engineering knowledge |

| PEO2 | Skills Make the graduates to apply their engineering and problem solving skills in professional engineering practices, tackle social problems and business challenges. |

| PEO3 | Attitude Train the graduates to adopt ethics and exhibit their effective skills in communication, teamwork and leadership qualities. |

Program Outcome

| PO1 | Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals and an engineering specialization to the solution of complex engineering problems. |

| PO2 | Problem analysis: Identify, formulate, review research literature and analyze complex engineering problems reaching substantiated conclusions with consideration for sustainable development |

| PO3 | Design/development of solutions: Design creative solutions for complex engineering problems and design/develop systems/components/processes to meet identified needs with consideration for the public health and safety, whole-life cost, net zero carbon, culture, society and environment as required. |

| PO4 | Conduct investigation of complex problems: Conduct investigations of complex engineering problems using research-based knowledge including design of experiments, modelling, analysis & interpretation of data to provide valid conclusions. |

| PO5 | Modern tool usage: Create, select and apply appropriate techniques, resources and modern engineering & IT tools, including prediction and modelling recognizing their limitations to solve complex engineering problems. |

| PO6 | The Engineer and The World: Analyze and evaluate societal and environmental aspects while solving complex engineering problems for its impact on sustainability with reference to economy, health, safety, legal framework, culture and environment |

| PO7 | Ethics: Apply ethical principles and commit to professional ethics, human values, diversity and inclusion; adhere to national & international laws |

| PO8 | Individual and Collaborative Team work: Function effectively as an individual, and as a member or leader in diverse/multi-disciplinary teams |

| PO9 | Communication: Communicate effectively and inclusively within the engineering community and society at large,such as being able to comprehend and write effective reports and design documentation, make effective presentations considering cultural, language, and learning differences. |

| PO10 | Project Management and Finance: Apply knowledge and understanding of engineering management principles and economic decision-making and apply these to one’s own work, as a member and leader in a team, and to manage projects and in multidisciplinary environments. |

| PO11 | Life-Long Learning: Recognize the need for, and have the preparation and ability for i) independent and life-long learning ii) adaptability to new and emerging technologies and iii) critical thinking in the broadest context of technological change. |

Program Specific Outcomes(PSOs)

| PSO1 | Ability to solve complex engineering problems in Design, Manufacturing and Thermal engineering industries. |

| PSO2 | Inculcate curiosity for developing innovative ideas and entrepreneurship through interdisciplinary learning. |

- Vision

- Mission

To impart outstanding Education to the learners.

To provide platform for the learners to explore their innovative and creative skills.

To encourage to engage in research and innovation beneficial to the society.

Groom Engineering and entrepreneurship skills on par with social ethics.

Enhance interaction with industry to develop learners career.

- DAC

Roles and Responsibilities

The Department Advisory Committee interacts and maintains liaison with key stakeholders.

- The Department Advisory Committee is chaired by HOD who receives the report of the Department Advisory Committee and monitors the progress of the program.

- The committee develops and recommends new or revised goals and objectives of the program.

- The committee also reviews and analyzes the gap between curriculum and Industry requirement and gives necessary feedback or advice actions.

- NPTEL, Spoken tutorial , FDP, STTP / Guest lecturers monitoring

- Verification of Faculty Dairy for the following:

a. Attendance Entry,

b. Class and Series Test Marks,

c. Syllabus Coverage,

d. Identification of Slow Learners and above average performers

e. HOD Authentication. - Verification of Assessment & Tutorial Sheets.

- Checking Course plan and delivery

- Submission of report to the IQAC in the prescribed format.

Meetings: Once in a Semester

Following are the members of advisory board:

| Si No | Name | Designation |

|---|---|---|

| 1 | Dr. Ansal Muhammed | Convener DAC(HOD) |

| 2 | Mr. Jeevan Ealias | IQAC (DAC) Department Coordinator |

| 3 | Mr.Rafeek Sidhic | Senior Faculty 2 |

| 4 | Mr. Kurian Varghese (Director Metrolla steels Ltd.) | Industrial Expert |

| 5 | Mr. Sajeeb Rahman(MITS) | Member from nearby Institute |

| 6 | Mr. Justin Sunny | Alumni |

| 7 | Mr. Jose Mathew | Parent |

- Staff Profile

Head of the Department

Dr. Ansal Muhammed K

Date of Joining: 25/01/2012

Qualification:Ph.D

mechhod@icet.ac.in

Regular Faculty

Mr. Rafeek Sidhic

Date of Joining: 20/08/2009

Qualification:M.Tech

rafeeksidhic@icet.ac.in

Mr.Jeevan Ealias

Date of Joining: 01/07/2013

Qualification:Ph.D(Pursuing)

jeevanealias@icet.ac.in

Mr.Eldose K.E.

Date of Joining: 18/01/2016

Qualification:M.Tech

eldoseke@icet.ac.in

Mr.Bobin Jacob

Date of Joining: 02/08/2019

Qualification:M.Tech

bobinjacob@icet.ac.in

Mr. Dileep K. S.

Date of Joining: 13/08/2020

Qualification:M.Tech

dileepks@icet.ac.in

Mr. Rejith R.

Date of Joining: 03/06/2024

Qualification:M.Tech

rejithr@icet.ac.in

Mr. Saeed Shamly K S

Date of Joining: 20/08/2025

Qualification:Ph.D(Pursuing)

saeedshamlyks@icet.ac.in

Visiting Faculty

Mr. George Thomas

Visiting Faculty

Date of Joining: 01/08/2019

Qualification:M.Tech

georgepando@gmail.com

Mr. Vimal Kumar

Visiting Faculty

Date of Joining: 01/08/2018

Qualification:B.Tech

ceo@innovations.com

Lab Instructors

Mr. Shefeeq P Y

Lab Instructor

Date of Joining: 18/11/2024

Qualification:ITI/ITC

shefeeqpy@icet.ac.in

Mr. Narayanan Nair P. G.

Lab Instructor

Date of Joining: 18/11/2024

Qualification:Diploma

narayanannair@icet.ac.in

Mr. Narayanan Nair K.P

Lab Instructor

Date of Joining: 03/02/2025

Qualification:Diploma

kpnarayanannair@icet.ac.in

- Facilities

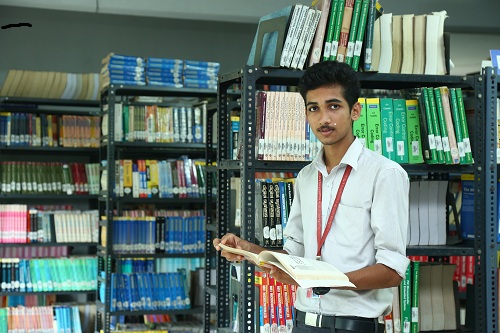

Department Library

The Department of Mechanical Engineering offers a comprehensive collection of textbooks, reference materials, technical journals, project reports, and conference proceedings covering core areas such as Design, Manufacturing, Thermal Engineering, and emerging interdisciplinary fields. With a quiet and focused study environment, the library also offers access to digital resources and online databases, fostering a culture of continuous learning and innovation. It plays a vital role in enriching the academic experience and encouraging scholarly excellence within the department

Library Rules

- Identity Card is compulsory for getting access to the library

- Silence to be maintained

- Using Mobile phones and audio instruments with or without speaker or headphone is strictly prohibited in the library premises.

- Enter the name and signature in the register kept at the entrance before entering library

- The librarian may recall any book from any member at any time and the member shall return the same immediately.

Manufacturing Technology Laboratory 1

The Manufacturing Technology Lab – I offers hands-on training in fundamental machining and manufacturing processes. Equipped with lathes, shapers, drilling machines, and fitting tools, the lab familiarizes students with operations like turning, drilling, shaping, and basic assembly. It emphasizes precision, safety, and process understanding, bridging the gap between theoretical concepts and real-world manufacturing practices

Laboratory facilities:-

- Centre lathe – 19

- Horizontal milling machine -3

- Sensitive drilling machine – 1

- Bench grinder – 1

- Power hack saw – 1

- Shaper – 10

- Slotter – 10

- Surface grinder – 1

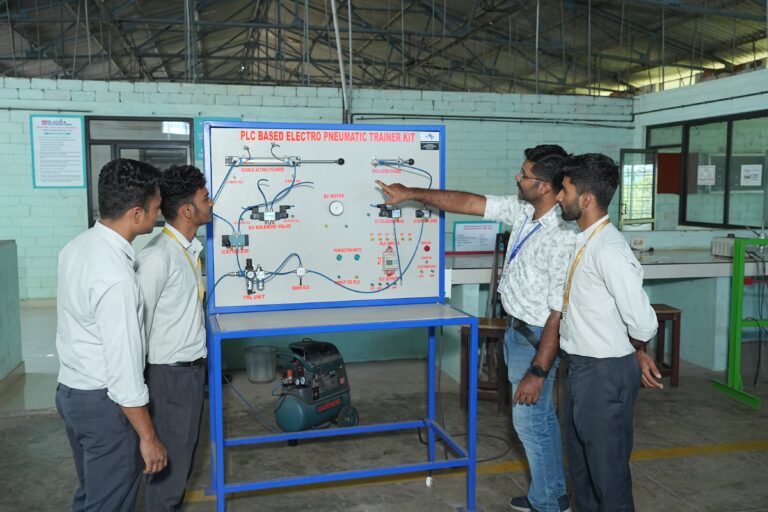

Mechanical System Laboratory

The Mechanical Systems Laboratory is designed to provide students with practical exposure to the principles and operations of various mechanical systems. This laboratory supports the academic curriculum by enabling hands-on learning in areas such as kinematics, dynamics of machines, vibration analysis, mechanisms, and control systems. Equipped with a range of modern apparatus—including gyroscopes, governor mechanisms, balancing machines, cam analysis setups, and vibration test rigs—the lab allows students to analyze real-time system behaviors and validate theoretical concepts. It plays a crucial role in enhancing students’ analytical, diagnostic, and design skills, ensuring they are industry-ready and capable of solving complex engineering challenges in mechanical system design and analysis

The experiments includes:

- Helical spring

- Static and Dynamic loading apparatus

- Cam analysis apparatus

- Centrifugal blower

- Two stage air compressor

- Whirling shaft apparatus

- Watt governor

- Dunkerley’s apparatus

Manufacturing Technology Laboratory 2

The aim of the Manufacturing Technology Laboratory – II is to provide students with advanced practical training in modern manufacturing processes such as CNC machining, Shaping, Slottering, and Metal forming. The lab enables students to understand the principles, operations, and applications of various production techniques, enhancing their proficiency in handling industrial-grade equipment and fostering readiness for real-world manufacturing environments.

Laboratory Equipments are:-

- Horizontal milling machine -3

- CNC – 1

- Sensitive drilling machine – 1

- Bench grinder – 1

- Power hack saw – 1

- Shaper – 10

- Slotter – 10

- Surface grinder -1

Fluid Mechanics and Hydraulic Machines Laboratory

The fluid Mechanics Lab mainly focused on determination of flow parameters related to fluid flow in pipes and open channels. The lab helps to getting idea about calibration of venturimeter, orifice meter, notches, etc.

After completing this lab, the students can able to have hands on experience in flow measurements using different devices and also perform calculation related to losses in pipes and also perform characteristic study of pumps, turbines etc.,

List Of Experiments

1.Determination of the Coefficient of discharge of given Orifice meter.

2.Determination of the Coefficient of discharge of given Venturimeter.

3.Calculation of the rate of flow using Rota meter.

4.Determination of friction factor for a given set of pipes.

5.Conducting experiments and drawing the characteristic curves of centrifugal pump/ submergible pump

6.Conducting experiments and drawing the characteristic curves of reciprocating pump.

7.Conducting experiments and drawing the characteristic curves of Gear pump.

8.Conducting experiments and drawing the characteristic curves of Pelton wheel.

9.Conducting experiments and drawing the characteristics curves of Francis turbine.

10. Determination of the Coefficient of discharge of rectangular and triangular notches.

11. Determination of the metacentric height of given floating body.

Mechanical Engineering Workshop

Mechanical Engineering Workshop is a place where students can acquire knowledge on the operation of various processes involved in manufacturing and production. The Workshop Practice Course makes students competent in handling practical work in Engineering environment.

Mechanical Workshop mainly includes Fitting, Carpentry, Smithy, Sheet Metal, Foundry and Welding sessions. The course is mandatory in the first year during their Engineering journey.

CAD Laboratory

CAD (Computer Aided Design) provides a convenient mean to create designs for almost every engineering discipline. It can be used for architectural design, landscape design, interior design, mechanical design, plant design, industrial design, duct design and product design. The laboratory will help the students to model the machnines in 2D and 3D and also to anlayze the same using computer software packages like AutoCAD, Ansys, etc.

The following are the main objectives of CAD Lab:

- To present an overview of CADD and describe its applications in different fields.

- To describe common terms associated with CADD hardware and software.

- Model the 3-D geometric information of machine components including assemblies, and automatically generate 2-D production drawings.

- Understand the basic analytical fundamentals that are used to create and manipulate geometric models in a computer program.

- Improve visualization ability of machine components and assemblies before their actual fabrication through modelling, animation, shading, rendering, etc.

- Model complex shapes including freeform curves and surfaces.

Thermal Engineering Laboratory

This course is aimed to provide students with practical exposure to the principles of thermodynamics and heat transfer through experiments on engines, compressors, and heat exchangers. The lab helps students to analyze the performance of thermal systems, understand energy conversion processes, and apply theoretical concepts to real-world engineering applications.

The Lab comprising of:-

- 2- Stroke Petrol Engine

- 4- Stroke Petrol Engine

- 3- Cylinder Maruti Petrol Engine

- 4- Stroke Single Cylinder Diesel Engine

- 4- Stroke Twin Cylinder Kirloskar Diesel Engine

- Single Cylinder Kirloskar Diesel Engine

- Single Cylinder Vertical Diesel Engine

- 4- Stroke Single Cylinder Kirloskar Diesel Engine

- 2 Stage Air Compressor

- Multi- Cylinder Petrol Engine Test Rig-Isuzu

Material Testing Laboratory

Materials Testing Laboratory includes a range of highly precise and reliable techniques that determine and measure the characteristics of materials, mechanical properties, elemental composition, corrosion resistance and the effects of heat treatments.

The laboratory is equipped with sophisticated equipments like Universal Testing Machine, Hardness Testing machine, Impact Testing machine, Torsion Testing Machine etc. The purpose of this laboratory experiments is to understand various aspects of mechanics of materials through laboratory analysis.

The Lab is equipped with:-

- Spring Testing Machine

- Impact Testing Machine

- Torsion Testing Machine

- Universal Testing Machine

- Rockwell Hardness Testing Machine

- Brinell Hardness Testing Machine

- Metallurgical Microscope

- Vickers Hardness Testing Machine

- Department Association

The Mechanical Engineering Association, established in 2006, aims to enrich and enhance students’ technical capabilities by organizing and participating in seminars, workshops, and various academic activities. This initiative is designed to cultivate essential skills such as leadership, teamwork, presentation, and effective communication.

Aims and Objectives

To foster interest and engagement in diverse technical domains within the field of Mechanical Engineering.

To bridge the gap between industry and academia by organizing expert lectures and talks delivered by distinguished professionals from the industry.

MECHANICAL ENGINEERING DEPARTMENT ASSOCIATION 2024-2025 ACADEMIC YEAR

EXECUTIVE COMMITTEE MEMBERS FOR ACADEMIC YEAR 2024-2025

| Si No | Name | Designation & Position |

|---|---|---|

| 1 | Dr. Faizal M H | HOD (ME) |

| 2 | Mr. Rafeek Sidhic | Assistant Professor& Staff Secretary |

| 3 | Mr. Muhammed Nihad | Student President |

| 4 | Mr Arjun K | Student Secretary |

| 5 | Mr Afsal P I | Student Treasurer |

| 6 | Mr Gokul T K, Mr. Muhammed Salim | 1st Year Student Representative |

| 7 | Mr. Dil N Krishnan, Mr. Muhammed Alshas | 2nd Year Student Representative |

| 8 | Mr. Aslam Muhammed, Mr. Jishnu Santhosh, Mr. Asif Ali | 3rd Year Student Representative |

| 9 | Mr. Muhammed Moosa, Mr. Thanseel Ashraf, Mr. Alex M Reji | 4th Year Student Representative |

- Achievements

100% Placement Achievement

We are proud to announce that the Department of Mechanical Engineering at Ilahia College of Engineering and Technology (ICET) has achieved an outstanding 100% placement for the Academic Year 2024–2025 in core mechanical companies.

This achievement highlights the department’s strong academic foundation, industry-relevant training, and exceptional student performance.

Placed in Top Mechanical Core Companies:

Ashok Leyland

NSK Bearings India Pvt. Ltd.

Stanadyne India

ZF Commercial Vehicle Control Systems

OUR TOPPERS – 2025

Top CGPA holders in 2024 – 2025 Academic Year

- Mr. Badhusha Salem received a token of appreciation for his outstanding academic performance in the seventh semester.

- Mr. Dil N Krishnan received a token of appreciation for his outstanding academic performance in third semester.

- Mr. Jishnu Santhosh received a token of appreciation for his outstanding academic performance in fifth semester.

- Events

AVENIR 2K25

The inauguration of the Mechanical Engineering Department Association – Avenir 2025 – was marked by a one-day technical talk held on 19th February 2025 at the college seminar hall. The session was led by Dr. Pradeep S, Assistant Vice President at NEST Digital.

- Handouts

Semester -8 | ||||||

| MET402 MECHATRONICS | Module-II | Module-III | Module-IV | Module-V | Module-VI | |

| MET414 QUALITY MANAGEMENT | Module-I | Module-II | Module-III | Module-IV | Module-V | Module-VI |

| MET 466 TECHNOLOGY MANAGEMENT | Course Notes (Module I to Module VI) | |||||

| MET 458 ADVANCED ENERGY ENGINEERING | ||||||

| University Question Paper | MET402 | MET414 | MET 466 | MET 458 | ME 404 | CE 494 |

Semester -7 | |||||||

| MET401 DESIGN OF MACHINE ELEMENTS | Module-II | Module-III | Module-IV | Module-V | Module-VI | ||

| MET473 AIR CONDITIONING AND REFRIGERATION | |||||||

| MET445 RENEWABLE ENERGY ENGINEERING | |||||||

| MCN401 INDUSTRIAL SAFETY ENGINEERING | Module-I | Module-II | Module-III | Module-IV | Module-V | Module-VI | |

| University Question Paper | ME 401 | MET473 | MET445 | MCN401 | ME 405 | ME 409 | ME 403 |

Semester -6 | |||||||

| MET302 HEAT & MASS TRANSFER | Module-II | Module-III | Module-IV | Module-V | Module-VI | ||

| MET304 DYNAMICS OF MACHINERY & MACHINE DESIGN | Module-I | Module-II | Module-III | Module-IV | Module-V | Module-VI | |

| University Question Paper | ME 302 | ME 304 | ME 306 | ME 308 | ME 312 | ME 366 | ME 368 |

Semester -4 | ||||||

| MET202 ENGINEERING THERMODYNAMICS | Module-II | Module-III | Module-IV | Module-V | Module-VI | |

| MET204 MANUFACTURING PROCESS | Course Notes (Module I to Module VI) | |||||

- Faculty Advisors

| Academic Year | Faculty Advisors |

|---|---|

| 2024-2028 | Dr. Ansal Muhammed K, Mr. Bobin Jacob |

| 2023-2027 | Mr. Jeevan Ealias |

| 2022-2026 | Mr. Rafeek sidhic, Mr. Dileep K S |

| 2021–2025 | Mr. Pramod Ramakrishnan, Mr. Eldose K E |

- Industrial Interactions

| Si.No | Industry | Place |

|---|---|---|

| 1 | United NDT Cochin | 32/110–B/C,RajTower, Chathangattu Road , Palarivattom , Cochin-25., Palarivattam, India, Kerala |

| 2 | Metrolla Steels Limited | Payipra Cheruvattoor Rd, Pezhakkappilly, Kerala 686673 |

| 3 | Auto soul Technologies Private Limited | Pankavil House, Kanjiramattom, Thodupuzha East P.O., Idukki 685585 |

| 4 | VI Innovations Private Limited BIMIT, kaloor | 2/455, Vishnusree , Perumkulangara, Kottaayi Palakkad 678572 |

| 5 | Sithara Plastic Private Limited | Malayattoor P O Ernakulam, Kerala |

- Stream Coordinators

| Streams | Subjects | Stream Coordinators |

| Fluid & Thermal Science | MET 203- Mechanics of Fluids | Mr. Bobin Jacob (Head) Mr. Eldose K E

|

| MET 303- Thermal Engineering | ||

| MET 202- Engineering Thermodynamics | ||

| MET 206- Fluid Machinery | ||

| MEL 202 – Fluid Mechanics & H M Lab | ||

| MEL 333 – Thermal Engineering Lab – 1 | ||

| MET 302- Heat & Mass Transfer | ||

| MEL 411- Mechanical Engineering Lab | ||

| MEL 334 Thermal Engineering Lab – II | ||

| Design Engineering Courses | EST 200 – Design & Engineering | Mr.Rafeek Sidhic (Head) Mr. Dileep K S Mr. Pramod Ramakrishnan |

| MET 201- Mechanics of Solids | ||

| MEL 201- Computer Aided Machine Drawing | ||

| MET 301- Mechanics of Machinery | ||

| MET 304- Dynamics and Design of Machinery | ||

| MEL 332- Computer-Aided Design & Analysis Lab | ||

| MET 401- Design of Machine Elements | ||

| Production & Industrial Engineering | MET 205- Metallurgy & Material Science | Mr. Ansal Muhammed K (Head) Mr. Rafeek Sidhic

|

| MET 204- Manufacturing Process | ||

| MEL 204 – Machine Tools Lab – I | ||

| MET 306- Advanced Manufacturing Engineering | ||

| MET 307- Machine Tools and Metrology | ||

| MEL 331- Machine Tools Lab – II | ||

| MET305 INDUSTRIAL & SYSTEMS ENGINEERING | ||

| HUT300 INDUSTRIAL ECONOMICS AND FOREIGN TRADE | ||

| HUT310 MANAGEMENT FOR ENGINEERS | ||

| MCN301 DISASTER MANAGEMENT | ||

| HUT300 INDUSTRIAL ECONOMICS AND FOREIGN TRADE | ||

| HUT310 MANAGEMENT FOR ENGINEERS | ||

| MET 312- Non-Destructive Testing | ||

| MET413 ADVANCED METHODS IN NONDESTRUCTIVE TESTING | ||

| MET445 RENEWABLE ENERGY ENGINEERING | ||

| MCN401 INDUSTRIAL SAFETY ENGINEERING | ||

| MET402 MECHATRONICS | ||

| Basic Engineering Courses | EST 120 – BASICS OF CIVIL & MECHANICAL ENGINEERING | Prof. Dr. Faisal M.H. (Head) Mr. Rafeek Sidhic Mr. Jeevan Ealias |

| ESL 120 CIVIL & MECHANICAL WORKSHOP | ||

| HUT200 PROFESSIONAL ETHICS | ||

| MCN201 SUSTAINABLE ENGINEERING | ||

| MCN202 CONSTITUTION OF INDIA | ||

| EST 110 ENGINEERING GRAPHICS | ||

| Seminar & Project | MEQ413 SEMINAR | Mr.Dileep K S (Head) Mr. Rafeek Sidhic |

| MET308 COMPREHENSIVE COURSE WORK | ||

| MED416 PROJECT PHASE II | ||

| MET404 COMPREHENSIVE VIVA VOCE |

- Results and Rank

- Elbin Jose, a student of Mechanical Engineering (Batch 2020–2024), secured a CGPA of 7.42 in the KTU Examination 2024

Pride of Mechanical Engineering

S.No. | Name of the Student | Batch | Percentage/ CGPA |

1 | Mr. Elbin Jose | 2020-2024 | 7.42 |

Toppers

2024-2025 Year

Name of Student | Semester | Batch | CGPA |

Badhusha Salim | 7th semester | 2021-2025 | 7.73 |

| Jishnu Santhosh | 5th semester | 2022-2026 | 8.10 |

| Dil N Krishnan | 3rd semester | 2023-2027 | 6.83 |

| Faizal Abdul aziz | 1st semester | 2024-2028 | 7.78 |

- Industrial Visits

(2024-2025) Year

| Si No | Visited Place | Semester | No. Of Students | Staff Accompanied |

|---|---|---|---|---|

| 1 | Kullu Shawl Factory , Manali | 2021-2025 Batch (S8) | 15 | Mr. Shefeeq P Y |

| 2 | German Spring Industry, Maharashtra | 2022-2026 Batch (S6) | 19 | Mr. Pramod Ramakrishnan |

| 3 | Vishal Industries, Mysore. | 2023-2027 Batch (S4) | 9 | Mr. Pramod Ramakrishnan |

| 4 | Kanan Devan Hills Plantations Company, Munnar | 2017-2021 Batch (S2) | 27 | Mr.Bobin Jacob |

- Department Library

Department Library

The Department of Mechanical Engineering offers a comprehensive collection of textbooks, reference materials, technical journals, project reports, and conference proceedings covering core areas such as Design, Manufacturing, Thermal Engineering, and emerging interdisciplinary fields. With a quiet and focused study environment, the library also offers access to digital resources and online databases, fostering a culture of continuous learning and innovation. It plays a vital role in enriching the academic experience and encouraging scholarly excellence within the department

Library Rules

- Identity Card is compulsory for getting access to the library

- Silence to be maintained

- Using Mobile phones and audio instruments with or without speaker or headphone is strictly prohibited in the library premises.

- Enter the name and signature in the register kept at the entrance before entering library

- The librarian may recall any book from any member at any time and the member shall return the same immediately.

- Downloads

| Program | Year | Document | Download Link |

|---|---|---|---|

| B.Tech Full Time | 2024 | Curriculum | Download |

| B.Tech Full Time | 2024 | Syllabus (S1-S2) | 1ST YEAR SYLLABUS_KTU_GROUPC |

| B.Tech Full Time | 2024 | Syllabus (S3-S8) | (S3Mechanical Engineering (2)-S8)-Download |

| B.Tech Full Time | 2019 | Curriculum | Download |

| B.Tech Full Time | 2019 | Syllabus | DMechanicalEngineeringS1-S8ownload |